Over the past 90 years, Attero has proven to be a leader in large-scale innovations in waste transportation and waste management. In some cases, Attero was even way ahead of the developments. Consider the first domestic waste separation plants in Wijster, for example, which only now are being recognised as full-fledged post-separation concepts. Attero is also often at the forefront of new developments in composting and anaerobic digestion. Just think of the anaerobic digestion concept in Venlo in combination with the development of certified substrate feedstock. Attero is a leader in plastic recycling as well. The first processing concepts date back as far as 1978. The historical timeline provides a digital overview of 10 highlights and important milestones achieved by Attero and its predecessors.

Attero: the Netherlands’ first and largest composting company

1929 -1985

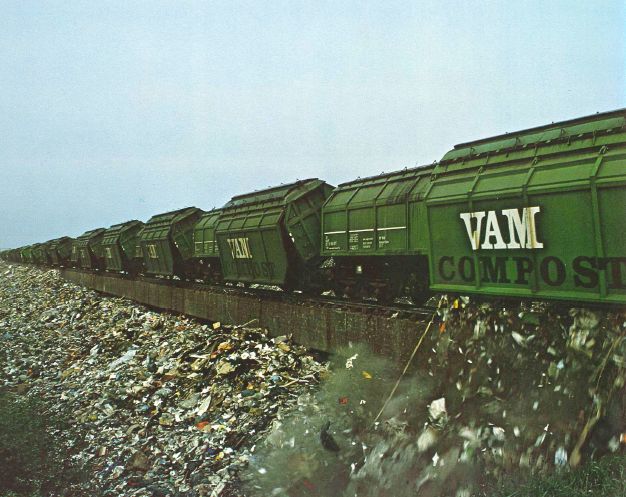

Attero's predecessor, Vuil Afvoer Maatschappij VAM, was incorporated in 1929. Waste from The Hague was transported to Wijster by train. There, domestic waste was converted into household compost to improve the barren soils of Drenthe, a Dutch province.

Attero, first gas extraction from landfills in Europe

1997-2019

In the past, waste sent to landfills still contained a great deal of organic material, such as paper and catering waste. Anaerobic decomposition of this organic material releases the greenhouse gas methane. Starting in 1987, Attero was the first company in Europe to develop a system with horizontal and vertical gas channels to capture the biogas released from landfills and convert it into green gas and electricity.

Attero, the first and largest closed composting facility in Europe

1994

The separate collection of biowaste became mandatory in the Netherlands in 1994. In a short period of time, a great deal of biowaste was collected while the processing capacity was not sufficient yet. That is why the largest closed composting facility in Europe was built in Wijster, with a licensed capacity of 480,000 tonnes per year. Attero is still the market leader in the Netherlands with 7 processing plants for biowaste.

Attero, the Netherlands’ first residual waste sorting plants

1980

Attero started separating waste early on. The first outlines of a domestic waste separation plan came about in the late 1970s. The first concept involved the Flakt plant in Wijster, followed by the domestic waste separation plant (HVS) at VAGRON in Groningen and VAT in Wijster. The concept of subsequent separation of waste was further optimised and later applied at the integrated waste treatment plant (GAVI) in Wijster.

Attero, the first integrated waste treatment plant in Europe

1996

The integrated waste treatment plant (GAVI) is unique because here the waste is first separated before entering the waste-to-energy plant. Metal, OWF (organic wet fraction), paper and plastic are removed first. What remains is incinerated. The heat from the incinerators drives the turbine that produces electricity. The site also supplies heat to nearby industry.

Attero, the first large-scale digester in the Netherlands

2008

The first full-scale dry digester for processing biowaste was built at Attero's Wilp location in 2008. At a later stage, Attero built 3 other digesters, each with their own specific technology. In Wijster, 2 vertical digesters were built: 1 for biowaste and 1 for the organic fraction from domestic waste. In Tilburg, a digester for swill-like streams was built in addition to the biowaste digester. In Venlo, a 2-stage digester was built in combination with a unique rinsing system to produce compost low in salt.

Attero, the first sorting plant for PMD PSP separated at the source and/or separated post-collection

2015

Dutch households and businesses throw away hundreds of thousands of tonnes of plastic packaging, beverage cartons and metal packaging every year. We reintroduce this so-called PMD waste into the cycle through our Plastic Sorting Plant (PSP). As the first and largest post-collection separator in the Netherlands, Attero also recovers a significant portion of these plastics, metals and beverage cartons from residual waste. This means that packaging separated at the source and packaging separated post-collection are recycled, so that nothing is wasted.

Attero, flexible supply of heat and electricity from waste-to-energy plants

2017

Residual waste from the Netherlands and countries including England and Ireland is fuel for our efficient waste-to-energy plants in Moerdijk and Wijster. Our plants are both unique and, from an environmental and technical point of view, are among the best in the world. After wind power, all waste-to-energy plants in our country make the largest contribution to the amount of sustainably produced energy. Attero's largest plant is located in Moerdijk. This plant switches flexibly between the production of renewable electricity and sustainable heat for industry.

Attero, first upcycling plant for film packaging waste separated at the source or separated post-collection

2018

Attero invested 30 million euros in the construction of the Polymers Recycling Plant at the Wijster location. This plant reprocesses plastic bags and other films from household waste into high-quality regranulate. Attero thereby takes an important step in closing the cycle for this type of plastic (LDPE). The plant was opened on 15 March 2019 by Mr Frans Timmermans, First Vice-President of the European Commission.