Packaging waste is increasingly being recycled. This can be done through source separation of PMD (plastics, metals and beverage cartons) or post-collection separation. With post-collection separation, smart technologies are used to separate the PMD from the waste after being collected. We can do both. You can choose for source separation or post-collection separation depending on what works best for you.

Sorting source-separated PMD

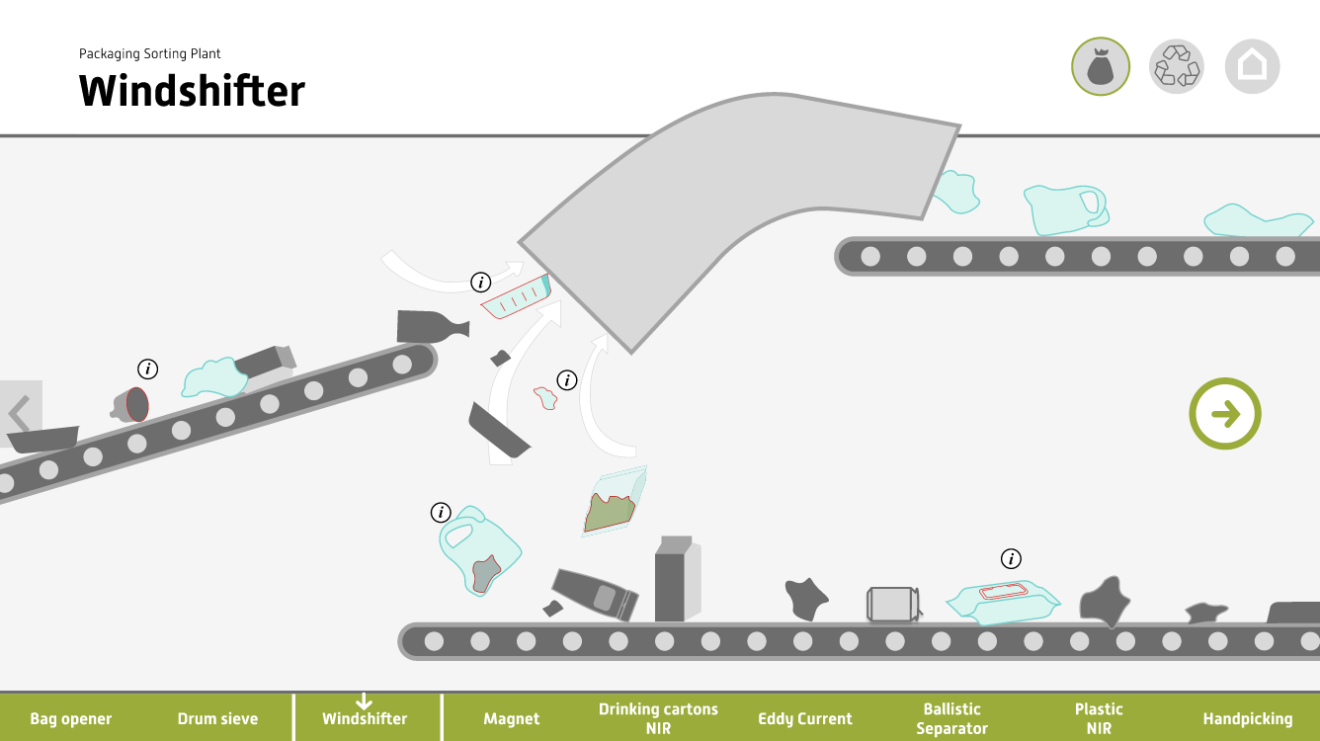

When separating at the source, Attero sorts the PMD delivered at its Packaging Sorting Plant (PSP) in Wijster into different monostreams. A variety of techniques is used to separate the following streams: PET bottles, PET trays, foils, HDPE, PP, mix plastics, beverage cartons, ferrous metals, non-ferrous metals and residue. Black plastics are also sorted. Through continuous improvements and reinvestments, Attero now has a best-in-class sorting plant with incredible sorting efficiency. Output quality is in line with the German DKR quality specifications. For sorted streams where technology is not flawless, manual quality control takes place as is also common in other sorting plants. The sorted materials are pressed into bales and sold to recyclers in the Netherlands and other European countries to be made into new products. The largest plastic packaging streams – films and mixed plastics – are recycled by Attero itself in Wijster.

Post-collection separation

In 1980, Attero became the first company in the Netherlands that offered post-collection separation thanks to its innovative plant in Wijster. With all the knowledge gained, we now operate a state-of-the-art post-collection separation plant. We see post-collection separation as a fully viable alternative to the source-separated collection of PMD packaging material.

In post-collection separation, the organic material present in the waste is first screened out. This Organic Wet Fraction is processed in our anaerobic digestion plant to produce green gas. The rest of the waste is ran through separators to separate the plastics, metals and beverage cartons. This mixed post-separated PMD stream is then sorted as a separate batch in our Packaging Sorting Plant (PSP), where source-separated PMD is also sorted.

Plastic recycling

In 2019, Frans Timmermans, First Vice President of the European Commission, and our Chief Executive Officer Paul Ganzeboom opened our Polymer Recycling Plant (PRP). At this innovative facility, Attero recycles contaminated films and mixed plastics from post-collection separation and PMD sorting into high-quality regranulate. The plant was created in part thanks to a European LIFE grant and praised for its innovative nature. Read more about the AGANFOILS-project.

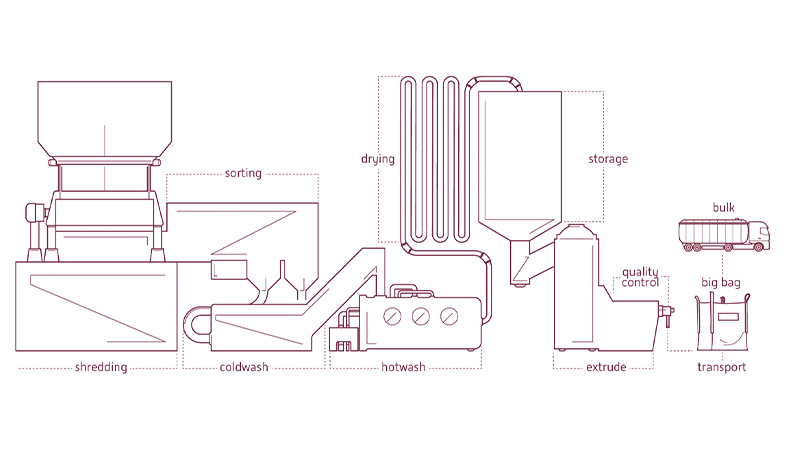

The plastics are first reduced to flakes in the PRP and then cold and hot washed, using cleaning agents. The heat required is supplied by our waste-to-energy plant. Intensive washing neatly removes any dirt, paper labelling and grease, leaving clean flakes. We put these flakes through our extruder, which turns the plastic into regranulate using pressure and heat.