AGANFOILS by Attero

Attero sorts foils from the domestic residual waste and PMD-waste (Plastic Metal Beverage Cartons) by separation of the plastics, in an integrated separation plant in the Energy from Waste plant. The plastics, are sorted into mono-streams, together with MSW (Municipal Solid Waste), by the separation plant for plastics. The LDPE-foils from domestic waste collection are separated in this plant by means of mechanical technics, windshifters and infra-red-detection.

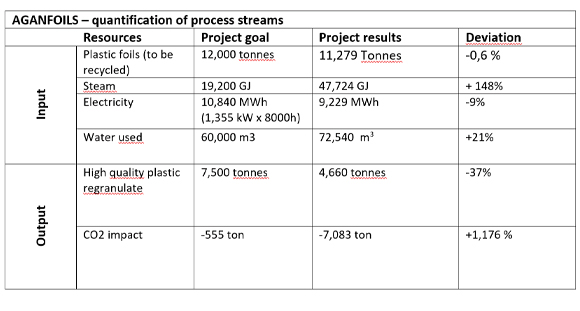

With the support of European LIFE programme, Attero has built a factory where these foils from domestic waste collection, with help of durable produced steam and electricity from the Energy from Waste Plant are shredded, sorted and washed hot and cold, to be recycled into LDPE granulate.

This regranulate can replace virgin fossil plastic raw materials. Because of this the regranulate-granules, produced by Attero, can offer an important contribution to the circular chain of plastics. By reusing the plastics, we limit the use of new plastics in the chain and we limit the impact on the environment.