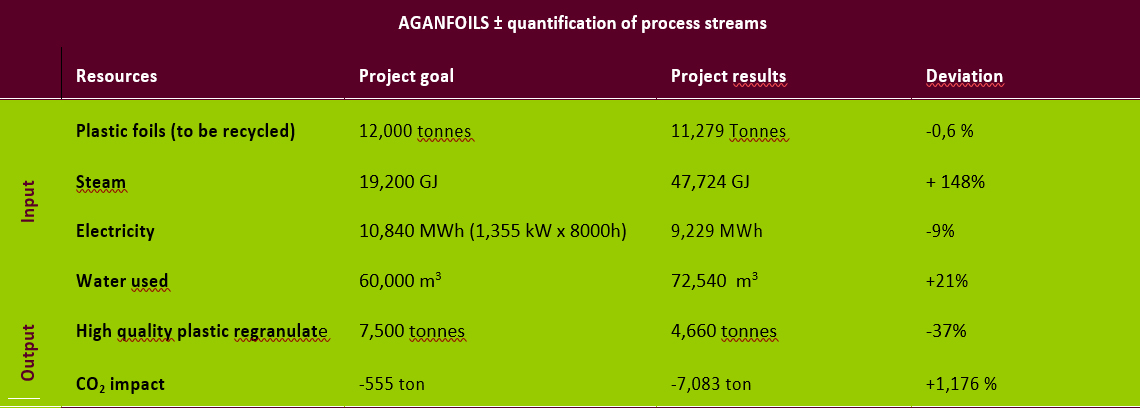

Projectname: AGANFOILS – As Good as New Foils. Projectnumber: LIFE15ENV/NL/000429.

Project objectives

Objective 1

Demonstrating that post-consumer foil can be recycled into a high quality plastic regranulate with a good efficiency in a sustainable and economic way, which reduces the need for virgin material.

This objective is met. Attero has succeeded to produce LDPE granulate, of 100% recycled foils from municipal waste, with its process. In a number of products this material is used in the meantime for production of plastic end-products without usage of virgin material. Because of the relatively high pollution rate of the feedstock foil that is processed, we have a relatively high amount of residue to meet the quality requirements of our customers. The residue however contains a high amount of plastics (mixture of all kinds of plastics) and we are in the process of finding recycling outlets for these plastics, so the beneficial yield will rise. Total yield can grow up to 65%, which brings the efficiency to the desired level. The regranulate quality is good now and could be used for blown film production, but is mainly being applied in the thick-layered market for economic reasons only. The oil-prices have been relatively low, so prices of virgin plastics have been at the lower end as well, making the prices for regranulate fall below the anticipated business case level. Processors are using virgin material, because of the low pricing and because reuse of plastics is not mandatory. With the oil prices recovering and the anticipated legislation for the mandatory application of recycled content we forecast regranulate prices to be driven up to make the economics work. We see the first signs of this development in the market currently. The current focus of producing regranulates at thick-layered market quality has the benefit of a better availability of the production lines and a higher yield.

Objective 2

Demonstrating an integrated full-industrial scale waste-to-resource plastic recycling process by using state of the art equipment in a smart sequence and combining the recycling stage with an existing MRF.

This objective is met. The existing separation of plastics from municipal waste, followed by sorting of the different plastics in several mono-streams, has been extended with a dedicated recycling installation. In this process, all sorted foils are converted in a reusable LDPE-granulate successfully.

Objective 3

Reducing the environmental impact of the plastic recycling process, through the efficient use of available residual energy and water streams and reduction of CO2 emission related to transport.

This objective is met. Because the Plastic Recycling Plant is situated on the site of the waste processing plant, the energy supply can be provided by residual heat and electricity that is released during the processing of residual waste. Also the environmentally harmful transport is prevented because the recycling plant is situated directly next to the location of the sorting plant for plastics.